Traditional caramelizing pans, typically made of copper or stainless steel, provide excellent heat distribution but require careful temperature control to prevent burning. Induction-ready caramelizing pans offer rapid, precise heating and energy efficiency, making them ideal for caramelizing pet treats quickly and evenly. Choosing the right pan enhances caramelization quality, ensuring a perfectly crisp and flavorful coating.

Table of Comparison

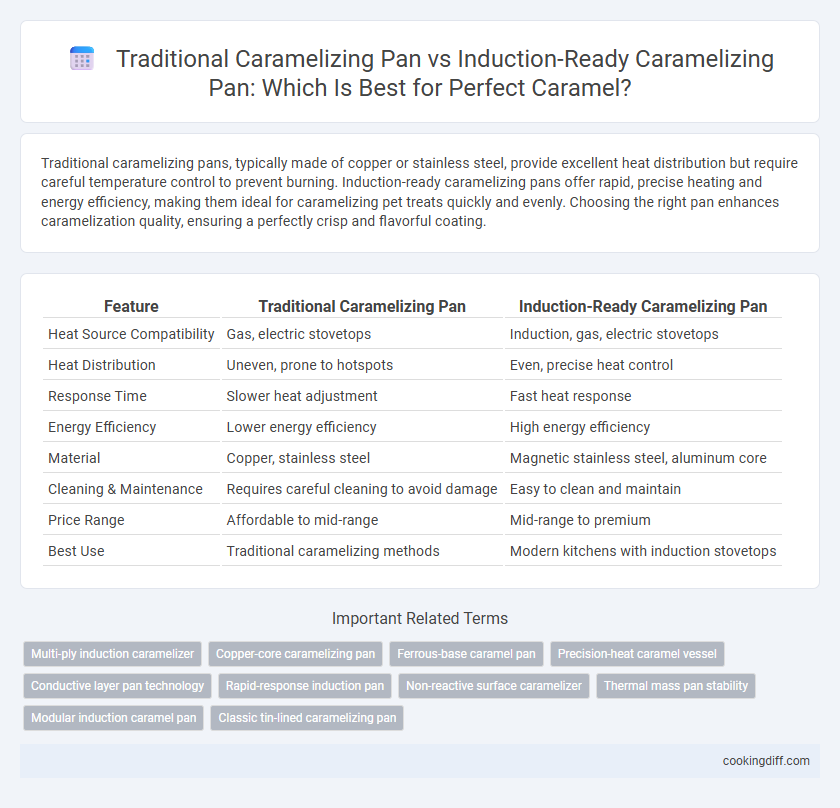

| Feature | Traditional Caramelizing Pan | Induction-Ready Caramelizing Pan |

|---|---|---|

| Heat Source Compatibility | Gas, electric stovetops | Induction, gas, electric stovetops |

| Heat Distribution | Uneven, prone to hotspots | Even, precise heat control |

| Response Time | Slower heat adjustment | Fast heat response |

| Energy Efficiency | Lower energy efficiency | High energy efficiency |

| Material | Copper, stainless steel | Magnetic stainless steel, aluminum core |

| Cleaning & Maintenance | Requires careful cleaning to avoid damage | Easy to clean and maintain |

| Price Range | Affordable to mid-range | Mid-range to premium |

| Best Use | Traditional caramelizing methods | Modern kitchens with induction stovetops |

Introduction to Caramelizing Techniques

Caramelizing transforms sugar and other ingredients through precise heat application, creating rich flavors and textures essential in many recipes. Choosing the right pan significantly impacts heat distribution and cooking results during caramelization.

- Traditional Caramelizing Pan - Offers even heat distribution with a heavy base, ideal for slow, controlled caramelization over gas or electric stovetops.

- Induction-Ready Caramelizing Pan - Designed with magnetic materials that enable fast, efficient heating on induction cooktops, improving temperature control.

- Heat Responsiveness - Induction pans generally provide quicker response to temperature changes compared to traditional pans, enhancing precision in caramelizing.

Selecting between these pans depends on your cooking method and the level of control required for optimal caramelization.

What is a Traditional Caramelizing Pan?

A traditional caramelizing pan is typically made from heavy-gauge stainless steel or copper, allowing for even heat distribution essential for the precise temperature control needed in caramelizing sugar. These pans often feature a wide, flat base and slightly sloped sides to facilitate easy stirring and prevent scorching. Unlike induction-ready pans, traditional caramelizing pans may not have a magnetic base, making them incompatible with induction cooktops.

Understanding Induction-Ready Caramelizing Pans

What makes induction-ready caramelizing pans more efficient than traditional caramelizing pans? Induction-ready caramelizing pans feature a magnetic base that ensures rapid and even heating, reducing cooking time significantly. Their compatibility with induction stovetops allows precise temperature control essential for perfect caramelization.

Heat Distribution in Traditional vs Induction-Ready Pans

Traditional caramelizing pans, often made from copper or heavy-gauge aluminum, provide excellent heat distribution, ensuring even caramelization without hot spots. Their material composition allows for precise temperature control, critical for achieving the perfect caramel color and flavor.

Induction-ready caramelizing pans feature a magnetic stainless steel base that promotes rapid and uniform heat transfer on induction cooktops. This technology ensures consistent heat distribution across the pan surface, reducing the risk of burning and enabling efficient caramelization at lower energy consumption.

Material Differences: Impact on Caramelization

Traditional caramelizing pans, often made from copper or stainless steel, provide excellent heat distribution essential for even caramelization. Induction-ready caramelizing pans feature a magnetic base that ensures rapid heating and precise temperature control, impacting the caramelization process by preventing hotspots and burning.

- Copper Pans - Offer superior thermal conductivity for consistent caramelization but require careful maintenance to prevent tarnishing.

- Stainless Steel Pans - Durable and resistant to corrosion, though they heat less evenly, potentially causing uneven caramelization.

- Induction-Ready Pans - Equipped with magnetic layers to support induction cooktops, these pans heat quickly and maintain stable temperatures, optimizing caramelization.

Energy Efficiency: Traditional vs Induction-Ready Pans

Traditional caramelizing pans typically use direct flame, resulting in uneven heat distribution and higher energy consumption. Induction-ready caramelizing pans offer superior energy efficiency by using magnetic induction to heat the pan directly, reducing heat loss and cooking time. This method ensures precise temperature control, enhancing caramelization quality while saving up to 70% of energy compared to traditional pans.

Temperature Control and Responsiveness

Induction-ready caramelizing pans offer superior temperature control and faster responsiveness compared to traditional caramelizing pans, enabling precise caramelization without burning. Traditional pans heat unevenly and slower, making temperature regulation more challenging and less efficient for delicate caramel processes.

- Induction-ready pans provide rapid temperature adjustments - Their magnetic base interacts directly with the cooktop, allowing immediate heat changes essential for perfect caramelization.

- Traditional pans have slower heat conduction - Materials like copper or aluminum heat unevenly, potentially causing hot spots and inconsistent caramel results.

- Induction-ready pans maintain steady temperatures - This stability helps prevent caramel from crystallizing or burning by ensuring precise heat control throughout cooking.

Maintenance and Durability Comparison

Traditional caramelizing pans, often made from copper or stainless steel, require frequent seasoning and careful cleaning to maintain their non-stick properties and prevent discoloration. Their durability is dependent on the quality of the metal and can suffer from warping or corrosion over time if not properly maintained.

Induction-ready caramelizing pans feature magnetic bases designed for even heat distribution and are typically coated with durable, non-stick surfaces that simplify cleaning and reduce maintenance efforts. They tend to have enhanced longevity due to corrosion-resistant materials and are less prone to warping under high heat conditions common in caramelizing processes.

Cost Considerations and Investment Value

| Traditional caramelizing pans typically have a lower upfront cost, making them a budget-friendly option for home cooks and small-scale use. Induction-ready caramelizing pans, though more expensive initially, offer enhanced energy efficiency and durability that can lead to long-term savings. Investing in an induction-compatible pan increases versatility and compatibility with modern cooktops, thereby providing greater value over time despite the higher initial price. |

Related Important Terms

Multi-ply induction caramelizer

Multi-ply induction caramelizers excel in heat distribution and retention, ensuring consistent caramelization without hot spots common in traditional caramelizing pans. Their magnetic base compatibility with induction cooktops offers rapid, precise temperature control, enhancing browning efficiency and reducing sugar scorching risks.

Copper-core caramelizing pan

Copper-core caramelizing pans offer superior heat conductivity and precise temperature control crucial for perfect caramelization, preventing hot spots and ensuring even browning. Compared to traditional pans, induction-ready copper-core pans combine this optimal thermal performance with compatibility on induction cooktops, enhancing efficiency and consistency during the caramelizing process.

Ferrous-base caramel pan

Ferrous-base caramel pans are essential for effective caramelizing due to their superior heat conductivity and even heat distribution, preventing hot spots that cause burning. Induction-ready ferrous pans enhance energy efficiency and compatibility with modern induction cooktops, ensuring consistent caramelization temperature control essential for perfect caramel textures.

Precision-heat caramel vessel

A precision-heat caramelizing pan designed for induction offers superior temperature control compared to traditional caramelizing pans, enabling consistent caramel development without hot spots. Its magnetic base ensures rapid, even heat distribution essential for perfect caramelization, enhancing flavor and texture precision.

Conductive layer pan technology

Traditional caramelizing pans rely on direct heat transfer through metal layers, often resulting in uneven temperature distribution and hot spots that can impact caramel quality. Induction-ready caramelizing pans feature advanced conductive layer technology, typically combining magnetic stainless steel with aluminum cores to ensure rapid, uniform heat conduction and precise temperature control critical for consistent caramelization.

Rapid-response induction pan

Rapid-response induction caramelizing pans heat evenly and quickly due to their magnetic stainless steel base, reducing the risk of burning sugar compared to traditional pans. Their precise temperature control ensures consistent caramelization, enhancing flavor development and texture in confectionery applications.

Non-reactive surface caramelizer

A traditional caramelizing pan often features a non-reactive surface like stainless steel or copper, which prevents acid in the sugar from reacting and altering the flavor during caramelization. Induction-ready caramelizing pans combine these non-reactive materials with magnetic bases, ensuring even heat distribution and compatibility with induction cooktops for precise temperature control.

Thermal mass pan stability

Traditional caramelizing pans typically feature higher thermal mass, providing stable, even heat distribution essential for uniform caramelization without hot spots, while induction-ready caramelizing pans often have lower thermal mass but respond quickly to temperature changes, allowing precise control but potentially requiring more careful heat management. The superior thermal mass stability of traditional pans ensures consistent caramel texture and reduces the risk of burning, making them preferred for slow, controlled caramelization processes.

Modular induction caramel pan

A modular induction caramelizing pan offers precise temperature control and rapid heat responsiveness, optimizing the caramelization process compared to traditional caramelizing pans that rely on uneven heat distribution. Its induction-ready design ensures energy efficiency and consistent browning, making it superior for achieving perfect caramel textures and flavors.

Traditional caramelizing pan vs induction-ready caramelizing pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com