Toasting seeds enhances their flavor by applying dry heat, resulting in a richer, nuttier taste and a crisp texture. Steam-toasting, by contrast, uses steam to heat the seeds, which can preserve more moisture and prevent burning but may yield a softer texture with less pronounced flavor development. Choosing between toasting and steam-toasting depends on the desired balance of flavor intensity and seed texture.

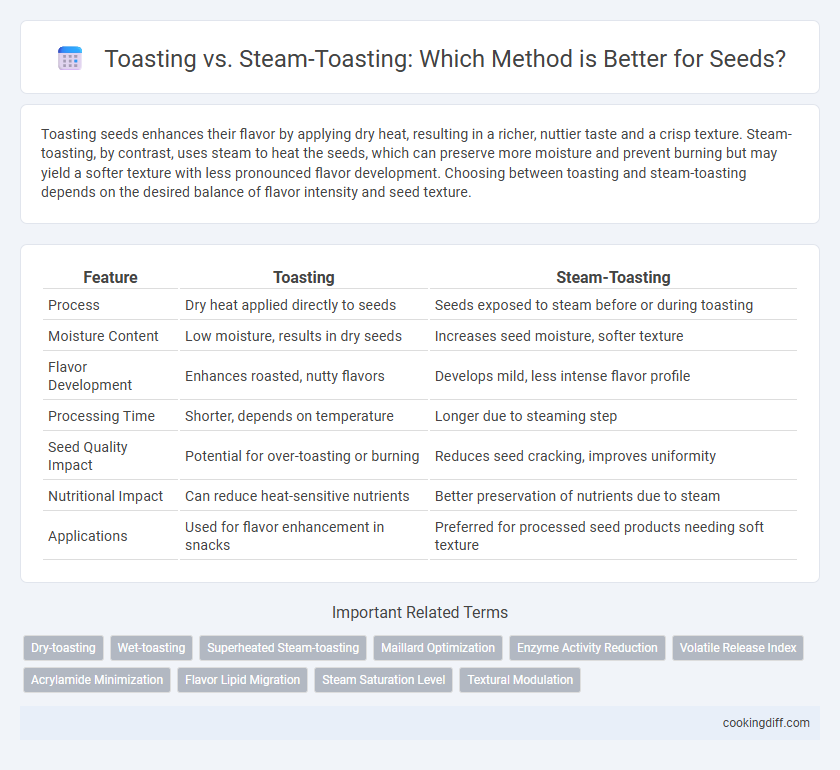

Table of Comparison

| Feature | Toasting | Steam-Toasting |

|---|---|---|

| Process | Dry heat applied directly to seeds | Seeds exposed to steam before or during toasting |

| Moisture Content | Low moisture, results in dry seeds | Increases seed moisture, softer texture |

| Flavor Development | Enhances roasted, nutty flavors | Develops mild, less intense flavor profile |

| Processing Time | Shorter, depends on temperature | Longer due to steaming step |

| Seed Quality Impact | Potential for over-toasting or burning | Reduces seed cracking, improves uniformity |

| Nutritional Impact | Can reduce heat-sensitive nutrients | Better preservation of nutrients due to steam |

| Applications | Used for flavor enhancement in snacks | Preferred for processed seed products needing soft texture |

Understanding Toasting and Steam-Toasting for Seeds

| Toasting seeds involves dry heat which enhances flavor through Maillard reactions, creating a nutty aroma and crunch without added moisture. |

| Steam-toasting seeds combines steam and heat, softening the seed coat and increasing nutrient bioavailability while maintaining moisture content. |

| Choosing between toasting and steam-toasting depends on desired texture, flavor profile, and nutritional goals for the seed product. |

The Science Behind Traditional Toasting

Traditional toasting employs dry heat to induce the Maillard reaction, enhancing the flavor and aroma of seeds by breaking down proteins and sugars. This process results in a distinct, nutty taste and a crunchy texture.

Steam-toasting integrates moisture with heat, which alters the seed's outer structure without fully drying it, preserving some natural oils and nutrients. The science behind this method involves partial gelatinization of starches and a milder Maillard reaction, leading to a softer texture. This technique can optimize seed palatability while maintaining higher nutritional value compared to traditional dry toasting.

How Steam-Toasting Works

Steam-toasting involves exposing seeds to high-temperature steam, which rapidly heats and softens the seed coat. This moist heat process helps to preserve the seed's natural oils and nutrients while enhancing flavor and texture.

Unlike dry toasting, steam-toasting reduces the risk of burning and uneven heating by maintaining consistent moisture levels. The method promotes better seed expansion and improves digestibility by breaking down complex compounds within the seed.

Flavor Profiles: Toasted vs Steam-Toasted Seeds

Toasting seeds enhances their nutty, rich flavor by applying dry heat, which caramelizes natural sugars and deepens aroma. Steam-toasting seeds produces a milder taste with retained moisture, resulting in a softer texture and subtle flavor notes.

- Toasted seeds develop a robust, toasted aroma - The dry heat intensifies the seeds' natural oils, creating a powerful and aromatic flavor profile.

- Steam-toasted seeds maintain higher moisture content - This process softens the seeds, preserving subtle, fresh flavors without the intensity of dry toasting.

- Flavor complexity differs significantly - Toasting yields bold, caramelized flavors while steam-toasting offers a delicate, mellow taste ideal for lighter culinary applications.

Nutritional Differences: Toasting Methods Compared

Toasting seeds enhances flavor through dry heat, preserving more antioxidants like vitamin E and phenolic compounds compared to steam-toasting. Steam-toasting introduces moisture, which can reduce certain heat-sensitive nutrients but may increase digestibility and reduce antinutrients such as phytic acid.

Studies show toasting maintains higher levels of lipids and vitamins, while steam-toasting better retains water-soluble nutrients like some B vitamins. Selecting a method depends on balancing nutrient retention with desired texture and flavor outcomes for optimal seed nutrition.

Texture Changes in Seeds: Toasting vs Steam-Toasting

Toasting seeds results in a dry, crunchy texture due to the Maillard reaction enhancing flavor and firmness. Steam-toasting seeds introduces moisture first, leading to a softer, puffier texture while still developing flavor.

- Toasting creates a crisp and crunchy texture - Dry heat removes moisture, intensifying seed firmness.

- Steam-toasting produces a softer, puffier seed - Steam adds moisture that expands seed structure before drying.

- Texture differences affect culinary uses - Toasted seeds suit crunchy toppings; steam-toasted seeds work in softer baked goods.

Health Impacts of Toasting Methods

Toasting seeds enhances flavor by applying dry heat, which preserves essential oil content and antioxidants better than steam-toasting, reducing nutrient loss. Steam-toasting exposes seeds to moisture and heat, which can cause some degradation of heat-sensitive vitamins and alter seed texture, potentially affecting digestibility. Health impacts favor dry toasting as it maintains higher levels of beneficial compounds such as polyphenols and essential fatty acids in seeds compared to steam-toasting.

Equipment Needed for Toasting and Steam-Toasting Seeds

Toasting seeds requires simple dry heat equipment like a skillet or oven, while steam-toasting involves specialized steamers or combination steam ovens for moisture infusion. Each method demands different tools to achieve optimal texture and flavor in seeds.

- Skillet or Oven - Basic equipment for dry toasting seeds, providing even heat distribution without moisture.

- Steamer or Steam Oven - Essential for steam-toasting seeds, allowing controlled moisture and heat application.

- Temperature Control - Precise heat settings are crucial in both methods to avoid burning or undercooking seeds.

Choosing the right equipment impacts the efficiency and quality of the toasting process for various seed types.

Best Seeds for Each Toasting Method

Sunflower and pumpkin seeds are ideal for dry toasting due to their robust texture and ability to develop a crunchy exterior without becoming soggy. Steam-toasting suits chia and flax seeds better, as the moisture helps unlock their natural oils and enhances flavor while preserving a softer texture. Selecting the right toasting method maximizes flavor and nutritional benefits specific to each seed type.

Related Important Terms

Dry-toasting

Dry-toasting seeds enhances their natural flavors and preserves nutrients by using direct heat without added moisture, resulting in a crisp texture ideal for snacking or recipes. Unlike steam-toasting, dry-toasting prevents seed sogginess and maintains optimal antioxidant levels, making it a preferred method for maximizing both taste and health benefits.

Wet-toasting

Wet-toasting seeds involves steaming them to retain moisture and enhance their flavor profile while preventing burning, unlike dry toasting which uses direct heat and risks charring. This method improves seed digestibility and preserves essential oils, resulting in a richer aroma and taste.

Superheated Steam-toasting

Superheated steam-toasting offers superior seed processing by combining intense heat with moisture control, resulting in enhanced flavor development and higher nutrient retention compared to traditional dry toasting. This method reduces oxidation and preserves essential oils, producing a more consistent and crispy seed texture ideal for premium snack products.

Maillard Optimization

Toasting seeds enhances flavor through the Maillard reaction by applying dry heat, which intensifies browning and creates complex taste compounds, whereas steam-toasting introduces moisture that can inhibit optimal Maillard reaction efficiency and result in less pronounced flavor development. Precise temperature control during dry toasting maximizes Maillard browning, improving seed aroma and texture without the dilution effect caused by steam.

Enzyme Activity Reduction

Toasting seeds effectively reduces enzyme activity by applying dry heat, which deactivates lipase enzymes responsible for rancidity, whereas steam-toasting uses moist heat that may not achieve the same level of enzyme inactivation. The dry heat in traditional toasting ensures better preservation of seed quality and longer shelf life by minimizing oxidative spoilage caused by residual enzyme activity.

Volatile Release Index

Toasting seeds releases a higher Volatile Release Index (VRI), enhancing aroma and flavor through Maillard reactions and caramelization. Steam-toasting, by contrast, produces a lower VRI by limiting heat intensity, resulting in milder volatile profiles and reduced loss of delicate aromatics.

Acrylamide Minimization

Toasting seeds at lower temperatures reduces acrylamide formation compared to steam-toasting, which involves higher moisture and heat that can increase acrylamide levels. Optimizing toasting temperature and time effectively minimizes acrylamide content while preserving seed flavor and nutritional quality.

Flavor Lipid Migration

Toasting seeds enhances flavor through Maillard reactions, promoting complex nutty notes by reducing moisture and activating surface sugars, while steam-toasting retains more moisture, limiting lipid migration and preserving seed freshness but resulting in milder flavor development. Lipid migration during dry toasting intensifies aromatic compounds as oils move to the seed surface, whereas steam-toasting minimizes this effect, maintaining integrity of seed lipids and subtle flavor profiles.

Steam Saturation Level

Steam-toasting seeds leverages a higher steam saturation level to enhance moisture penetration and uniform heat distribution, resulting in a more even roast and intensified flavor profile compared to traditional dry toasting. The controlled steam environment reduces seed scorching and preserves essential oils, optimizing both texture and nutritional value.

Toasting vs Steam-toasting for seeds. Infographic

cookingdiff.com

cookingdiff.com