Digital control offers superior precision in drying by allowing exact temperature settings, minimizing the risk of under- or over-drying. Temperature dials provide a simple and intuitive interface but often lack fine-tuning capabilities, resulting in less consistent results. For optimal dehydration, digital controls ensure stable and accurate temperature regulation, enhancing food quality and safety.

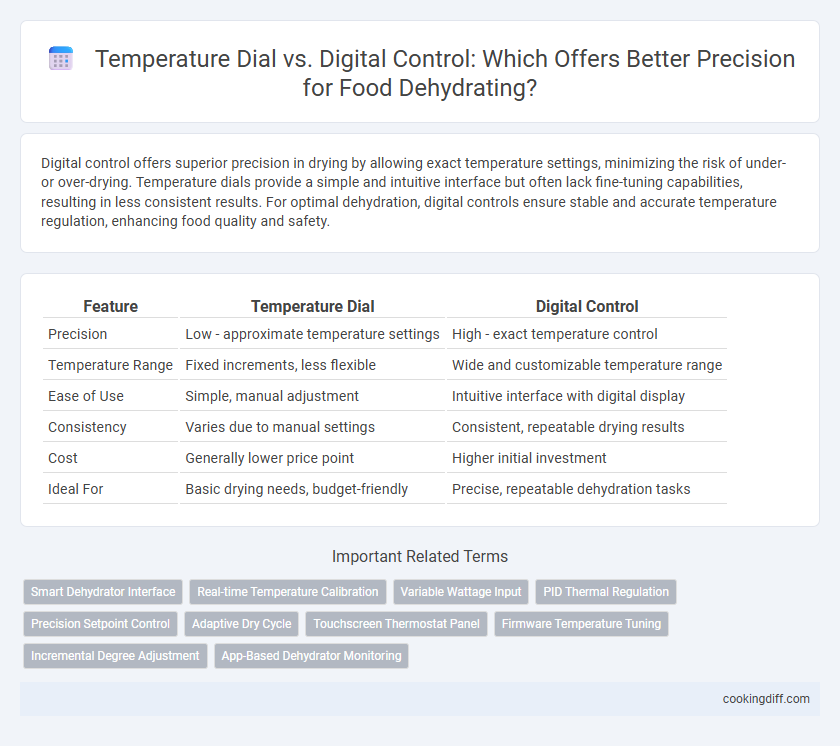

Table of Comparison

| Feature | Temperature Dial | Digital Control |

|---|---|---|

| Precision | Low - approximate temperature settings | High - exact temperature control |

| Temperature Range | Fixed increments, less flexible | Wide and customizable temperature range |

| Ease of Use | Simple, manual adjustment | Intuitive interface with digital display |

| Consistency | Varies due to manual settings | Consistent, repeatable drying results |

| Cost | Generally lower price point | Higher initial investment |

| Ideal For | Basic drying needs, budget-friendly | Precise, repeatable dehydration tasks |

Introduction to Precision Drying in Dehydrators

Temperature dial controls offer basic adjustment for dehydrator settings, allowing users to manually set drying temperatures within a limited range. This analog method provides tactile feedback but can lack exact temperature precision crucial for sensitive drying tasks.

Digital control systems enable precise temperature settings with accuracy to the degree, improving consistent drying results and reducing the risk of over- or under-drying. Advanced dehydrators with digital interfaces often include preset programs and timers that enhance ease of use and reproducibility in drying processes.

Understanding Temperature Dials in Food Dehydrators

How does a temperature dial compare to digital control for precision drying in food dehydrators? Temperature dials offer a straightforward way to adjust heat but can lack exactness, making it challenging to maintain consistent drying conditions. Digital controls allow precise temperature setting and monitoring, which enhances the reliability of the dehydration process and prevents over- or under-drying.

What Are Digital Controls?

Digital controls in dehydrators offer precise temperature settings through an electronic interface, allowing users to select exact degrees for optimal drying. Unlike temperature dials, digital controls maintain consistent heat without fluctuations, ensuring uniform dehydration of foods. This precision aids in preserving nutrients and achieving desired textures by preventing overheating or under-drying.

Accuracy: Temperature Dial vs Digital Control

Digital control offers superior accuracy in maintaining precise temperatures during dehydrating, usually within +-1degF, reducing the risk of over- or under-drying. Temperature dials, on the other hand, often provide less consistent temperature regulation with fluctuations up to +-5degF.

Accurate temperature control improves food safety and texture by ensuring even moisture removal. Digital controls enable users to set exact drying parameters, enhancing repeatability and overall dehydration quality.

Ease of Use and User Experience

Digital control offers precise temperature settings with easy-to-read displays, enhancing user experience through accuracy and convenience. Temperature dials provide a tactile, straightforward interface preferred by users seeking simplicity and quick adjustments.

- Digital Control Precision - Allows exact temperature input for consistent drying results and reduces guesswork.

- Temperature Dial Simplicity - Enables fast, intuitive adjustments without navigating complex menus.

- User Feedback - Digital controls often include timers and alerts, improving ease of monitoring and overall usability.

Energy Efficiency Considerations

Temperature dials offer basic control over drying conditions but often lack the precision needed for optimal energy efficiency. Digital controls provide exact temperature settings that prevent overheating and reduce unnecessary power consumption.

Digital control systems enable users to maintain consistent drying temperatures, improving energy use by avoiding fluctuations that lead to excessive energy waste. Precise temperature regulation minimizes the risk of over-drying and extends appliance lifespan, enhancing overall efficiency. Investing in digital controls can result in significant energy savings over time due to improved operational accuracy.

Maintenance and Durability

| Temperature dials offer mechanical simplicity, reducing the risk of electronic failure and lowering maintenance costs over time. Digital controls provide precise temperature settings, but their electronic components may require more frequent calibration and can be susceptible to moisture damage. For long-term durability, temperature dials are often preferred in harsh environments, while digital controls excel in applications demanding exact temperature accuracy. |

Cost Comparison: Analog vs Digital Options

Analog temperature dials typically cost less upfront but may lack the precise control needed for optimal dehydration results. Digital controls offer enhanced accuracy and programmable settings, which can lead to greater energy efficiency and better food preservation but usually come at a higher price.

- Lower initial cost - Analog dials are generally more affordable, making them attractive for budget-conscious users.

- Higher precision - Digital controls provide exact temperature adjustments, improving drying consistency.

- Long-term value - Despite higher initial costs, digital models can reduce energy waste and extend appliance life.

Impact on Food Quality and Consistency

Temperature dials offer a basic level of control, which can result in fluctuating drying temperatures affecting the consistency of moisture removal. Digital controls provide precise temperature settings, ensuring uniform drying and better preservation of food texture and nutrients.

- Temperature Dial - Allows manual adjustment but often leads to less accurate temperature control impacting food quality.

- Digital Control - Enables exact temperature regulation, improving consistency and reducing over-drying or under-drying risks.

- Food Quality Impact - Precise temperature consistency preserves flavor, color, and nutritional value more effectively with digital controls.

Choosing digital control enhances drying precision, leading to superior food quality and consistent results.

Related Important Terms

Smart Dehydrator Interface

Smart dehydrator interfaces with digital control offer precise temperature settings, ensuring consistent moisture removal and optimal nutrient retention during drying. Unlike traditional temperature dials, digital controls provide exact temperature adjustments, programmable timers, and real-time feedback to enhance drying accuracy and energy efficiency.

Real-time Temperature Calibration

Digital control systems offer real-time temperature calibration, ensuring consistent precision drying by automatically adjusting to maintain exact heat levels, unlike analog temperature dials that require manual calibration and can lead to temperature fluctuations. This advanced monitoring in digital dehydrators optimizes drying efficiency and preserves nutritional quality by preventing overheating or under-drying.

Variable Wattage Input

Temperature dials on dehydrators provide basic heat settings but often lack the precise control needed for consistent drying, especially when variable wattage input impacts temperature stability. Digital controls offer precise temperature adjustments and real-time feedback, optimizing drying accuracy by compensating for fluctuations in power supply and ensuring uniform moisture removal.

PID Thermal Regulation

Digital control with PID thermal regulation offers superior precision in dehydrating by maintaining consistent temperature levels, minimizing fluctuations that can compromise the drying process. Unlike traditional temperature dials, PID systems continuously monitor and adjust heat output to ensure optimal moisture removal and preserve food quality.

Precision Setpoint Control

Digital control offers superior precision setpoint control in dehydrating processes by allowing exact temperature adjustments to the nearest degree, reducing fluctuations and ensuring consistent drying results. Temperature dials provide less accuracy due to manual settings and potential calibration drift, which can compromise drying uniformity and product quality.

Adaptive Dry Cycle

Adaptive Dry Cycle technology enhances precision drying by continuously monitoring moisture levels and adjusting drying time and temperature for optimal results. Temperature dial controls offer basic settings, while digital control systems enable exact temperature adjustments, improving energy efficiency and preventing over-drying.

Touchscreen Thermostat Panel

Touchscreen thermostat panels offer superior temperature control for dehydrating, providing precise adjustments within 1-degree increments and real-time digital readouts that ensure consistent drying conditions. Unlike traditional temperature dials, touchscreen controls enhance accuracy, reduce user error, and allow programmable settings for customized drying cycles.

Firmware Temperature Tuning

Firmware temperature tuning in digital control systems enhances precision drying by allowing exact adjustments and real-time feedback, unlike temperature dials that rely on manual settings and lack accuracy. This capability in digital controllers optimizes dehydration efficiency and product quality by maintaining stable temperature profiles throughout the drying process.

Incremental Degree Adjustment

Digital controls offer precise incremental degree adjustments, typically in 1-degree increments, enabling consistent temperature settings for optimal dehydration results. In contrast, temperature dials often lack fine-tuning capability, leading to less exact drying cycles and potential variability in food texture and moisture content.

Temperature dial vs Digital control for precision drying. Infographic

cookingdiff.com

cookingdiff.com