Blanching effectively deactivates enzymes by applying heat, but it can cause nutrient loss and texture changes. Cryogenic blanching uses ultra-low temperatures with liquid nitrogen or carbon dioxide, preserving nutrients and texture while inactivating enzymes more rapidly. This method offers superior quality retention and energy efficiency compared to traditional blanching techniques.

Table of Comparison

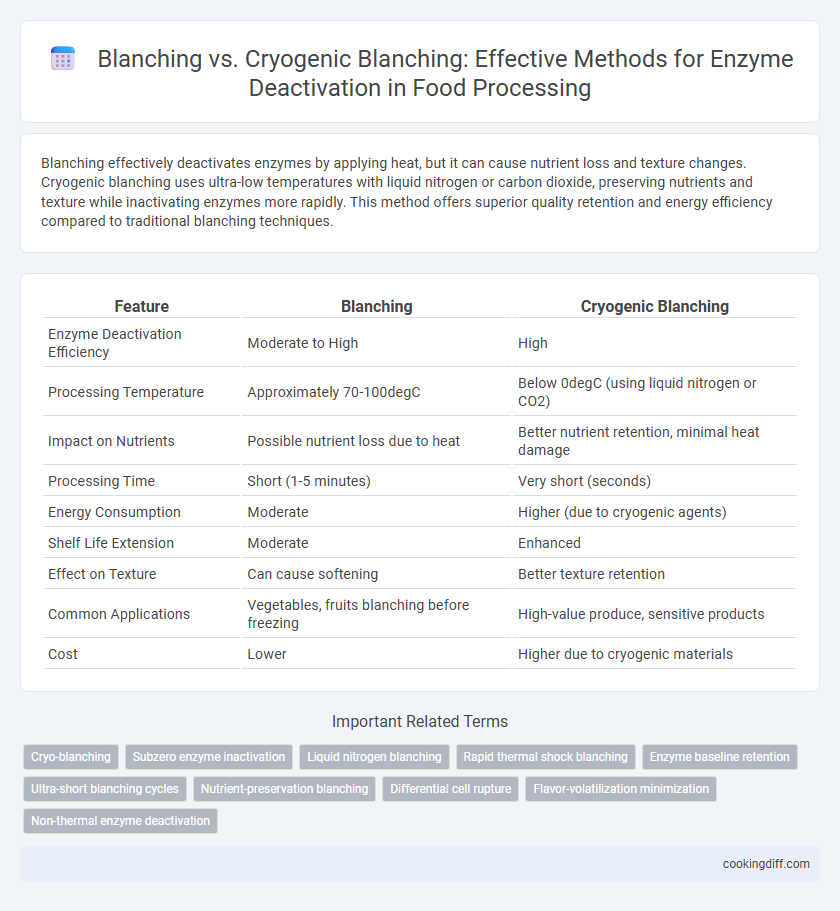

| Feature | Blanching | Cryogenic Blanching |

|---|---|---|

| Enzyme Deactivation Efficiency | Moderate to High | High |

| Processing Temperature | Approximately 70-100degC | Below 0degC (using liquid nitrogen or CO2) |

| Impact on Nutrients | Possible nutrient loss due to heat | Better nutrient retention, minimal heat damage |

| Processing Time | Short (1-5 minutes) | Very short (seconds) |

| Energy Consumption | Moderate | Higher (due to cryogenic agents) |

| Shelf Life Extension | Moderate | Enhanced |

| Effect on Texture | Can cause softening | Better texture retention |

| Common Applications | Vegetables, fruits blanching before freezing | High-value produce, sensitive products |

| Cost | Lower | Higher due to cryogenic materials |

Introduction to Blanching in Food Processing

Blanching in food processing involves briefly heating fruits or vegetables to inactivate enzymes that cause spoilage, preserving color, flavor, and texture. Traditional blanching uses hot water or steam, while cryogenic blanching employs extremely low temperatures with liquid nitrogen or carbon dioxide for rapid enzyme deactivation. Cryogenic blanching offers enhanced retention of nutrients and sensory qualities compared to conventional methods, making it a superior alternative for perishable food products.

Understanding Enzyme Deactivation and Its Importance

Enzyme deactivation during blanching is crucial to preserve food quality by inhibiting enzymatic reactions that lead to spoilage and discoloration. Traditional blanching uses hot water or steam to deactivate enzymes like peroxidase and polyphenol oxidase, but it may cause nutrient loss and texture changes. Cryogenic blanching employs ultra-low temperatures using liquid nitrogen or carbon dioxide, enabling rapid enzyme inactivation while maintaining nutritional content and sensory attributes more effectively.

Conventional Blanching: Methods and Effectiveness

Conventional blanching involves exposing food products to hot water or steam for a short duration to deactivate enzymes and preserve quality. This method effectively reduces enzymatic activity but can result in nutrient loss and texture changes due to heat exposure.

Hot water blanching immerses vegetables in water typically between 70-100degC, while steam blanching exposes them to steam at similar temperatures, both aiming to inactivate enzymes like polyphenol oxidase and peroxidase. The effectiveness depends on blanching time and temperature, balancing enzyme inactivation with minimal quality degradation. However, conventional blanching often leads to leaching of water-soluble vitamins and minerals, which can affect the nutritional value of the food.

What Is Cryogenic Blanching?

Cryogenic blanching is a process that uses ultra-low temperatures, typically involving liquid nitrogen or carbon dioxide, to deactivate enzymes in food products without applying heat. This method preserves color, texture, and nutritional value better than conventional hot water blanching by minimizing thermal degradation.

- Enzyme Deactivation - Cryogenic blanching rapidly inactivates enzymes responsible for spoilage and quality loss.

- Temperature Control - The extremely low temperatures prevent cooking or softening of the food's cellular structure.

- Nutrient Retention - Unlike traditional blanching, cryogenic blanching maintains higher levels of vitamins and antioxidants.

This innovative technique offers a superior alternative for preserving fresh produce quality during processing and storage.

Comparative Mechanisms: Traditional vs Cryogenic Blanching

Traditional blanching deactivates enzymes through heat-induced protein denaturation, typically involving soaking in hot water or steam at 70-100degC. Cryogenic blanching employs ultra-low temperatures using liquid nitrogen or carbon dioxide to rapidly inactivate enzymes by disrupting cellular structures without thermal damage.

- Heat Transfer Mechanism - Traditional blanching relies on conduction and convection heat transfer to raise the product temperature for enzyme deactivation.

- Cryogenic Shock - Cryogenic blanching causes rapid freezing and fracturing of cellular membranes, leading to enzyme inactivity through physical destabilization.

- Impact on Nutrients - Traditional blanching may cause nutrient leaching and degradation, while cryogenic blanching better preserves nutritional quality by minimizing heat exposure.

Impact on Nutritional Quality and Color Retention

Blanching effectively deactivates enzymes to preserve food quality but often leads to nutrient loss and color degradation due to heat exposure. Cryogenic blanching, using freezing temperatures, better maintains nutritional content and vibrant color by minimizing thermal damage.

- Nutrient Retention - Cryogenic blanching preserves vitamins and antioxidants more effectively than conventional blanching due to reduced heat exposure.

- Color Stability - Enzymatic browning is better inhibited in cryogenic blanching, resulting in brighter, fresher appearance of vegetables.

- Enzyme Deactivation Efficiency - Both methods deactivate enzymes effectively, but cryogenic blanching achieves this with less impact on food quality parameters.

Energy Efficiency and Sustainability Considerations

Blanching uses hot water or steam to deactivate enzymes, consuming significant energy due to prolonged heating. Cryogenic blanching employs ultra-low temperatures with liquid nitrogen, resulting in faster enzyme inactivation and lower overall energy consumption.

Cryogenic blanching supports sustainability by reducing carbon emissions linked to fossil fuel use in traditional blanching. Energy efficiency improvements in cryogenic methods contribute to decreased water usage and waste generation compared to conventional blanching processes.

Technological Challenges in Cryogenic Blanching

Cryogenic blanching faces significant technological challenges including the need for precise temperature control to ensure uniform enzyme deactivation without compromising food texture. The high cost and complexity of liquid nitrogen handling systems further limit its widespread adoption in the food processing industry.

Maintaining consistent product quality requires advanced monitoring and automation technologies to prevent uneven freezing or thermal shock. Integration of cryogenic blanching into existing production lines is hindered by equipment scalability and energy consumption concerns.

Food Industry Applications: Which Method Suits What Product?

| Blanching Method | Enzyme Deactivation Efficiency | Food Industry Applications | Suitable Products |

|---|---|---|---|

| Conventional Blanching | Moderate to high enzyme deactivation through heat treatment | Widely used in vegetable processing for color retention and texture softening | Leafy greens, root vegetables, and legumes requiring rapid heat penetration |

| Cryogenic Blanching | High enzyme deactivation with minimal thermal damage | Preferred in premium fruit and vegetable processing to preserve nutritional content and flavor | Delicate fruits, berries, and high-value produce sensitive to heat |

Related Important Terms

Cryo-blanching

Cryogenic blanching utilizes ultra-low temperatures, typically via liquid nitrogen, to rapidly inactivate enzymes in vegetables while preserving texture, color, and nutritional content more effectively than conventional hot-water blanching. This method minimizes thermal degradation and nutrient loss, making it superior for maintaining food quality during processing and storage.

Subzero enzyme inactivation

Cryogenic blanching uses subzero temperatures to achieve enzyme inactivation by rapidly lowering the temperature, effectively preserving food texture and nutrient content compared to traditional hot water or steam blanching. Subzero enzyme inactivation in cryogenic blanching minimizes thermal degradation and oxidative damage, optimizing food quality and shelf life.

Liquid nitrogen blanching

Cryogenic blanching using liquid nitrogen rapidly deactivates enzymes by instantaneously freezing the food surface, preserving texture and nutritional quality better than conventional hot-water blanching. This method minimizes thermal degradation while effectively inhibiting enzymatic activity, allowing extended shelf life and improved freshness in processed products.

Rapid thermal shock blanching

Rapid thermal shock blanching rapidly inactivates enzymes by exposing produce to sudden high temperatures, preventing enzymatic browning and texture degradation more efficiently than conventional methods. Compared to cryogenic blanching, this technique offers faster enzyme deactivation without the complexity and cost associated with liquid nitrogen or other cryogens.

Enzyme baseline retention

Blanching typically achieves enzyme deactivation by applying moderate heat, which can cause partial nutrient loss and variable enzyme baseline retention depending on temperature and time parameters. Cryogenic blanching, utilizing ultra-low temperatures such as liquid nitrogen, enhances enzyme inactivation efficiency while preserving higher enzyme baseline retention and nutrient integrity compared to conventional thermal methods.

Ultra-short blanching cycles

Ultra-short blanching cycles effectively deactivate enzymes by rapidly heating substrates, minimizing nutrient loss compared to conventional blanching methods. Cryogenic blanching, utilizing extremely low temperatures, offers enzymatic inactivation with improved retention of color and flavor but involves higher operational complexity and costs.

Nutrient-preservation blanching

Cryogenic blanching uses ultra-low temperatures to rapidly inactivate enzymes, significantly preserving vitamins and antioxidants compared to traditional hot water blanching. Nutrient-preservation blanching through cryogenic methods minimizes thermal degradation, retaining higher levels of heat-sensitive nutrients such as vitamin C and folate.

Differential cell rupture

Blanching causes cell rupture through heat-induced membrane disruption, leading to enzyme deactivation by denaturing enzymes within the cell. Cryogenic blanching achieves enzyme inactivation primarily via rapid freezing, which induces differential cell rupture by ice crystal formation, preserving texture while selectively damaging cellular structures associated with enzymatic activity.

Flavor-volatilization minimization

Cryogenic blanching utilizes ultra-low temperatures to effectively deactivate enzymes while preserving flavor compounds by minimizing volatilization, unlike traditional hot water blanching which often causes significant flavor loss due to heat exposure. This method maintains the sensory quality of foods by locking in volatile aromatic compounds, ensuring enhanced taste retention post-processing.

Blanching vs Cryogenic Blanching for enzyme deactivation. Infographic

cookingdiff.com

cookingdiff.com